Carey's Answers: Book #7

DDC & AI in Range Ventilation.

Powerful Ventilation Control Technology for Safety, Cost, Savings, and Maintenance.

Carey's Range Ventilation systems provide range owners with powerful, state of the art technology that is intuitive and easy to use. In this guide, we'll begin with a look at today's programmable DDC "smart" systems that provide range safety, energy cost savings and maintenance management. Then, we'll go beyond smart to explore emerging Artificial Intelligence (AI) algorithms that adapt to changing conditions as they write their own programs.

Using DDC to Assure Safety, Deduce Energy Costs and Manage Equipment Maintenance

The core capability of "smart" programmable Range Ventilation is Direct Digital Control (DDC), which provides three key benefits:

-

Most importantly, DDC assures safe range operations.

-

DDC reduces operating costs by avoiding wasteful power consumption.

-

DDc helps you anticipate and manage equipment maintenance requirements.

Q. How does the RV system assure safety on the range?

A.Carey’s RV system monitors the operation of the range including key health and safety parameters such as range supply airflow to the range space, filter conditions, and range negative pressure. Carey’s RV system will automatically alarm and shut down if conditions become unsafe for use. For example, it is essential that a negative pressure differential be maintained at all times between the range and outside areas to keep lead and other contaminants from entering surrounding areas. If this pressure is ever lost, an alarm sounds and range shuts down.

Q. How does the system adjust as the weather changes?

A. Carey’s RV systems include sensors and setpoints to automatically adjust heating and cooling to maintain supply temperature to the range. A controller on the range Recirculation System will automatically stage up and stage down the heating or cooling based on the difference between desired temperature and actual temperature. A higher stage will automatically engage if actual temperature is significantly different from desired temperature, while a lower stage will apply as actual temperature gets close to desired temperature.

Q. How do Variable Frequency Drives (VFD) save money?

A. VFDs provide soft starts on the motors, and allow the system to modulate the return fan speed to maintain negative pressure in the range space. This avoids the spike in power consumption that would otherwise occur from a hard start and also allows the system to modulate to maintain safety operating conditions.

Q. How can DDC help me anticipate equipment maintenance requirements and minimize downtime?

A.

DDC systems have enormous capacity to store data and crunch through calculations. You can minimize downtime by:

· Being reminded whenever filters and belts are due for replacement, so you can order parts and schedule maintenance well in advance of need.

· Being alerted whenever equipment may be about to malfunction … before the trouble actually starts. The controller recognizes patterns and can detect when a device is acting outside of its normal operating range.

· Providing system operating data to establish more cost effective maintenance programs.

This "smart" PCG Controller from Johnson Controls is used in Carey's RV systems. It communicates with Rooftop Unit (RTU) factory controllers to red and display operating data as well as diagnostic messages, and can be programmed to specific applications.

The experts are unequivocal

on the subject!

National Shooting Sports Foundation:

“All air being exhausted from the range should be passed through a High Efficiency Particulate Filter (HEPA) or equivalent to insure that state or federal regulations for airborne lead are not violated.”

National Air Filtration Association: “Exhaust or re-circulated air must be filtered at the point of removal with a minimum of 99.97% High Efficiency Particulate Air (HEPA) filter, per the Institute of Environmental Sciences and Technology (IEST) recommended practice. All HEPA filters should be accompanied by a letter of certification or a label documenting that each filter has met the test requirements.”

Click below to read more...

Carey's Simple, Intuitive User Interface Brings Powerful capabilities to Your Laptop

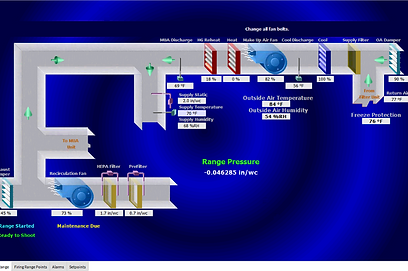

The Carey’s Graphic User Interface (GUI) lets you see exactly what’s happening throughout your Range Ventilation System. You can tell at a glance if your system is working properly. And, you can easily change set-points and other parameters from your laptop.

A purge heat system. Reminds operator of pending maintenance tasks and shows temperature set points and pressure differential.

A typical Recirculation System with full HVAC and humidity control.

Purge System operating data at a glance. Note cumulative run-times toward next scheduled maintenance that can be reset by operator.

Recirculation System operating data at a glance.

Artificial Intelligence (AI) in Range Ventilation

Q. What is Artificial Intelligence?

A. AI involves machines that are able to “learn” how to perform tasks by processing large amounts of data. In Range Ventilation, for example, there are hundreds and thousands of possible outcomes that would have to be programmed into a controller in order to achieve temperature and ventilation control that is “ideal” under all imaginable circumstances. Such a task would be humanly impossible. So, teaching machines to learn is a more effective way to reach all of these possible outcomes as the controller is able to program itself with a speed and accuracy that no humans can match.

Q. How does AI compare with today’s “smart” programmable controllers?

A. DDC controllers are called “smart” because they run very sophisticated programs (written by human engineers) that can be tailored to uniquely match a facility’s occupancy, weather, ventilation requirements and other parameters. AI takes this a step further with algorithms that can learn and adapt to changing surroundings. An AI system can modify its own program without human intervention.

Q. How is AI used in HVAC systems?

A. AI is a rapidly emerging field, and the use of AI and machine learning in HVAC systems continues to grow in its functionality. Most recently, AI-enabled systems have been able to forecast how to adjust temperatures by including longitudinal weather data with their algorithms. They have also been designed to detect an equipment malfunction before it is noticed by humans.

Q. What type of algorithm is used in AI systems?

A. The PCG Controllers in Carey’s RV systems use Pattern Recognition Adaptive Control (PRAC), an algorithm developed in the 1990’s and just now being applied outside the lab. Typically an HVAC system will change over time due to seasonal differences, building load changes and variations in the performance of HVAC devices such as air handling units, heat transfer pipes etc. These changes require a continual re-tuning process in order to achieve optimal control. Manual adjustment is difficult and labor-intensive; PRAC was invented to solve this problem with an adaptive algorithm.

Q. How is AI improving upon traditional Preventive Maintenance programs?

A.Machine learning (AI) is being developed to enable Predictive Maintenance which goes beyond traditional Preventive Maintenance. A strong maintenance program combines both approaches to manage equipment servicing and replacement.

Q. How do Predictive Maintenance and Preventive Maintenance work together?

A.Preventive Maintenance is driven by time or events that necessitate repair. Maintenance is scheduled while equipment is still in operation in order to prevent unplanned downtime and maximize the lifespan and productivity of equipment. While effective, there are certain drawbacks to using only this method. You run the risk of over-maintaining or under-maintaining your equipment since this method alone cannot take into account contextual information. Predictive Maintenance combines data from historical maintenance records, sensor data from equipment, and weather data to predict when a component will need to be serviced. This combination of data provides a contextual big picture that enables owners to make more informed decisions about when a component will need to be repaired or replaced. Predictive maintenance uses AI to translate massive amounts of data into meaningful insights and data points to quickly extract value from the data.

Q. Where can I find natural intelligence in Range Ventilation?

A.Call Carey’s today at (708) 532-2449 for a free consultation.

Q. Any more questions?

A. Call Carey’s today at (708) 532-2449 for a free consultation.